In one simple process, using Pulsar® Briquettes, the feeder:

- Chlorinates

- Shock treats

- Controls organics

- Boosts hardness

- Treats metals

In one simple process, using Pulsar® Briquettes, the feeder:

The new, highly-efficient design has many features to decrease maintenance and increase reliability.

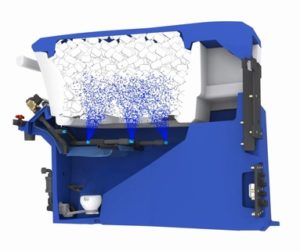

Spray Technology

Provides consistent dosing – up to 2.0% AvCl on demand

How it Works

Pool water enters the Pulsar® Feeder via the Feed and Wash inlet ports. A PLC (Programmable Logic Controller) controls dual solenoids to distribute the inlet water for optimum feeder efficiency. The Feed spray manifold and hopper are designed to provide a consistent chlorine solution concentration. Gravity draws the chlorinated solution into the discharge tank. The solution is discharged into the pool recirculation system via a booster pump/venturi system that can be programmed to maximize energy efficiency. Wash water flow is programmable to match varying feed rate and water chemistry conditions. The flow is controlled by a dedicated solenoid that directs the wash water to nozzles with unique spray patterns designed to remove residue from the internal components of the feeder.

Easy-to-Use Touchscreen Control Panel

• PLC (Programmable Logic Controller) based

• Can be programmed for use without ORP control

• Built in Pulsar CRS™ System control logic

• Touchscreen interface for easy control of feeder operations

• Includes alarm log, econ mode, and LSI calculation

• USB port for updating software

Efficient Design

• Improved carbon footprint

• Booster pump control option reduces energy consumption

Automated Cleaning Features

When the feed cycle is completed, the automatic wash-down nozzle cleans the inside of the feeder. The wash-down cycle:

• Is programmable using the Pulsar® Control Box

• Utilizes a second, dedicated solenoid

• Sprays and rinses both the spray shield and manifold periodic maintenance is normal and recommended.

• Use Pulsar® Acid Cleaner for best results.

• Water chemistry plays a significant part in your maintenance routine.

• All internal components easily accessible

• Common components across feeder line

• Removable solenoid assembly

• Quick disconnect fittings

• Supported by a nationwide network of Pulsar® Dealers

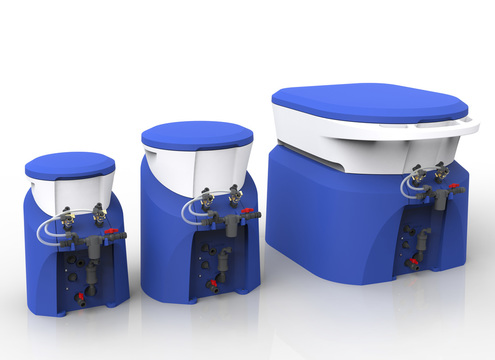

| Features | Pulsar® 45 Feeder | Pulsar® 140 Feeder | Pulsar® 500 Feeder |

|---|---|---|---|

| Recommended Pool Size (unstabilized, subject to local health codes) | 5,000 - 100,000 gallons | 15,000 - 200,000 gallons | 50,000 - 600,000 gallons |

| Recommended Pool Size (stabilized, subject to local health codes) | 50,000 - 150,000 gallons | 50,000 - 600,000 gallons | 100,000 - 1,600,000 gallons |

| Feed Rate (AvCl) (of Pulsar® Briquettes) | 2 - 58 lbs per day (with refills) | 5 - 163 lbs per day (with refills) | 25 - 486 lbs per day (with refills) |

| Feeder Height | 31" | 35" | 40" |

| Feeder Weight (full) | 55 lbs | 150 lbs | 465 lbs |

| Feeder Weight (empty) | 30 lbs | 50 lbs | 165 lbs |

| Capacity (of Pulsar® Briquettes) | 25 lbs | 100 lbs | 300 lbs |

| Downloadables |

Feeder brochure Installation manual Operator's manual |

Feeder brochure Installation manual Operator's manual |

Feeder brochure Installation manual Operator's manual |